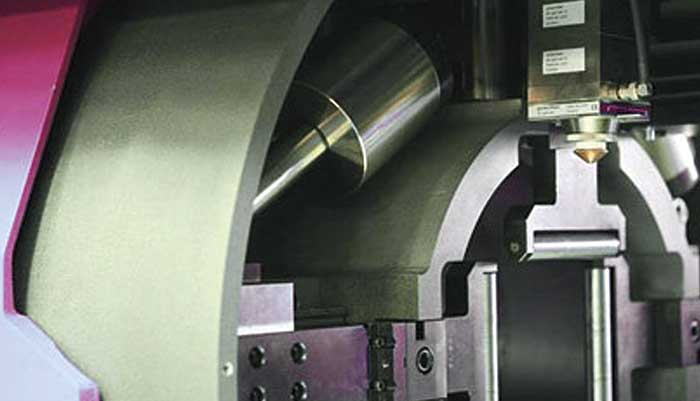

Tube Laser Cutting Systems 6090

The product images used are only for illustration and may not be exact representations of the product. Gulf States Saw & Machinery Co., Inc. reserves a right to amend product images or specifications at any given time.

Lasertube allows you to make suggestions for improvements to your customers' parts design. The extensive library of connections can be used for assembly without the use of screws or welding.